-

Mobile Version

Scan with Mobile

- Member Center

The lifting electromagnets produced by Hunan Huazhong Tiandi Environmental Protection Technology Co., Ltd. are widely used in the steel, machinery, foundry, port and mining industries for hoisting bulk ferromagnetic metal materials such as scrap steel, pig iron ingots, return materials and steel balls. They can also be used to lift medium and thick steel plates, slabs, workpieces, tools and castings, etc. There are various series such as small-sized, normal temperature, high temperature, ultra-high temperature, high frequency and submersible types, and can be customized according to requirements.

Product type (select based on the usage environment and job requirements)

1.normal temperaturetype

2. temperaturetype

3. frequencytype

4.Small electromagnet

This product is equipped with the standard type electronic control device by default. You can also choose the standard type, power-off magnetic protection type, or adjustable magnetic type. When using for weighing and batching, the adjustable magnetic type must be configured.

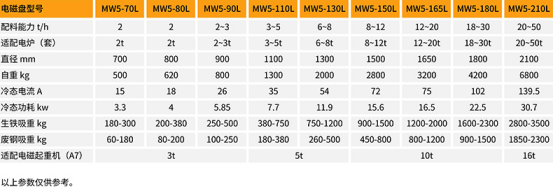

Selection Reference for Lifting Electromagnets

Technique Feature

1.The product has been optimally designed by computer. The magnetic circuit is more scientific and reasonable, with a large air-gap magnetic density and a deep permeation depth. The coil is made of aluminum wire (which can be replaced with copper wire), and the coil protection plate is made of rolled high manganese steel with good wear resistance and strong impact resistance. It is lightweight, has low energy consumption, a large lifting capacity, and a long service life.

2.The insulation grade is high. The insulation treatment adopts a unique process, which enhances the electrical and mechanical performance of the coil. The heat resistance grade of the insulation material can reach class C.

3.The voltage control method is usually adopted. If the strong excitation method (DC-290V/200V) is used, the lifting capacity can be further enhanced. For large electromagnetic coils, the over-excitation method (DC-350V/290V/200V) can be employed to accelerate the current rise rate and achieve a stronger lifting capacity.

Note: The actual lifting capacity of the electromagnetic hoist is related to the density of the material, its composition, and the condition of the contact surface.